What is sublimation printing?

Before we know what is Dye Sublimation Printing, we must know "what is sublimation" first.

We have learnt in Chemistry that an element or compound normally has 3 states i.e. solid, liquid and gaseous state and conversion from one state to another can happen by applying heat (solid>>liquid>>gaseous) or by removing heat (gaseous>>liquid>>solid). However, there are certain elements where only 2 states exist i.e. solid and gaseous. Thus in these elements, when heat is applied, an element gets transformed into gaseous form without intermediary liquid form (solid>>gaseous). This process of transformation is called "sublimation".

Dye Sublimation Printing uses above property to transfer any image / artwork from one surface to another. Popular uses are to transfer images on mugs, T-shirts, mousepads, etc.. A dye which sublimates under pressure and heat, is mixed with the inks.

You need following for Dye sublimation Printing

* an inkjet printer having Sublimation inks,

* sublimation paper,

* heat press and

* imprintables - also known as substrates (the surface on which image is to be transferred).

The first part of the process is very simple and resembles exactly to normal process of printing. How do we print something on paper using computer and desktop printer ? Precisely in the same manner, we print the artwork (as mirror image) on the sublimation paper using sublimation ink, through any DTP software like CorelDraw, PhotoShop, etc.. Here, instead of normal paper, sublimation paper is used and instead of normal ink, dye sublimation ink is used.

After printing, this paper is kept on the surface on which this artwork / image is to be transferred (with printed surface facing downwards on the surface) and heat and pressure is applied using a heat press. The ink sublimates i.e. converts to gaseous form and gets deposited "into" the surface, thus transferring image.

Sublimation transfers are made from special sublimation dyes that penetrate synthetic materials like polyester when you apply heat and pressure. During the transfer process, the dye heats up and turns into a gas that bonds with the synthetic portion of the fabric. No other decorating process can beat sublimation for the brilliance of color and durability. Because the sublimation process dyes the fibers of a garment, instead of putting a layer of ink on top of the fabric, the image cannot crack, peel, or wear off. The trade-off with using the sublimation process is that for the chemistry to work, it must be used with shirts that have a high polyester content (at least 50%).

Sublimation paper used is a specially coated paper which does not absorb the ink and thus helps in transferring maximum ink onto the surface of the immpritables.

What do you need to setup a branding business?

1. Epson printer with

Sublimation Ink

We recomend using an epson photo printer because of their ability to produce very sharp and clear images. Examples of these epson printer models are

a) Epson P50/ T50/ L800

These printers does a very good job and are affordable. The only limitation is that they can only print upto a maximum of A4 size.

b) Epson 1410/1430/1500W/ L1800

These models also does a very good job. Have similar print quality as the above models. The advantage of these models is in their size. These can print upto a maximum of A3 size and so will enable you to bigger images.

2. Heat press machine

We have different types of heapress machines depending on the imprintables that you want to brand. As we said earlier the purpose of a heatpress machine is to apply pressure and heat inorder for the ink to sublime and hence be transfered from the transfer paper to the substrate/imprintable.

a) Combo heatpress machines

These are all in ones heapress machines that can be used on a wide variety of imprintables. We have 5in1s , 8in1s etc depending on the number of imprintables. For example 5in1 can do

* ordinary mugs, * conical mugs, * plates, * caps, * t-shirts etc

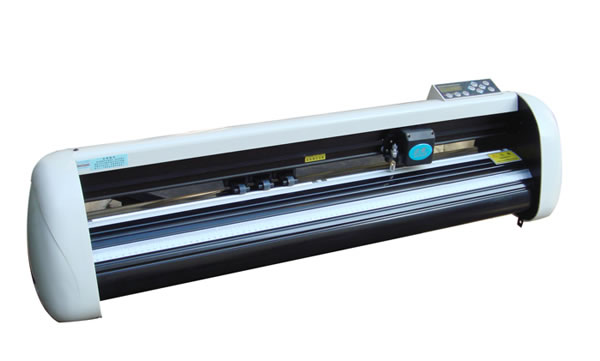

b) Single functions heatpress

These are specific to a particulartype of imprintable. These heatresses include

* mug heatpress, * plate heatpress, * flat bed heatpress etc

c) 3D vacuum heatpress

Unlike the above 2 that applies pressure by physically pressing on the substrates, the 3D heatpress uses vacuum to press. The advantage of this is that it can be used in irregularly shaped substrates such as rock etc. 3D heatpress can transfer to a wide range of items which includes iPhone and smart phone cover, mug, rim plate, rock, photo glass, crystal, glass goblet, beer mug, clothes, acrylic and metal plate.

3. Sublimation Imprintables &

sublimation papers

Last but not least, you will need the special coated substrates or the imprintables to transfer to, as well as special transfer papers to use to do the transfer. The impritables include coated mugs, plates, phone covers, t-shirts etc. The sublimation papers are available at our shop at very good prices. Also we have a wide variety of sublimation mugs also going at very cheap prices. We have ordinary sublimation mugs going for 130KES, color changing mugs, luminous mugs (glows in the dark) as well as conical mugs.

Our objective is to bring to you the most innovative & affordable printing solutions with 1 main goal:- to help you maximise your profits!